Innovative, cost-saving solutions for the most challenging water problems.

Whether your requirements are standard or unique, we can develop a specific treatment system to meet your needs now, and anticipated needs in the future.

A fluid approach to water treatment.

Wastewater treatment runs the gamut from relatively straightforward to highly complex—and rarely are two water problems the same. Our team combines scientific and cross-disciplinary field expertise with a varied tech stack to work with customers to achieve their water treatment goals.

Because we’re not tethered to one particular technology we have the flexibility to work within your current system, assemble a state-of-the-art stack based on your unique requirements, and adapt and respond treatment to fluctuating conditions.

Water treatment services:

Wastewater and septic tank treatment

Landfill leachate

Suspended solids removal from construction and development sites

Contaminated dredge water, including saltwater

Industrial

Agricultural

Potable

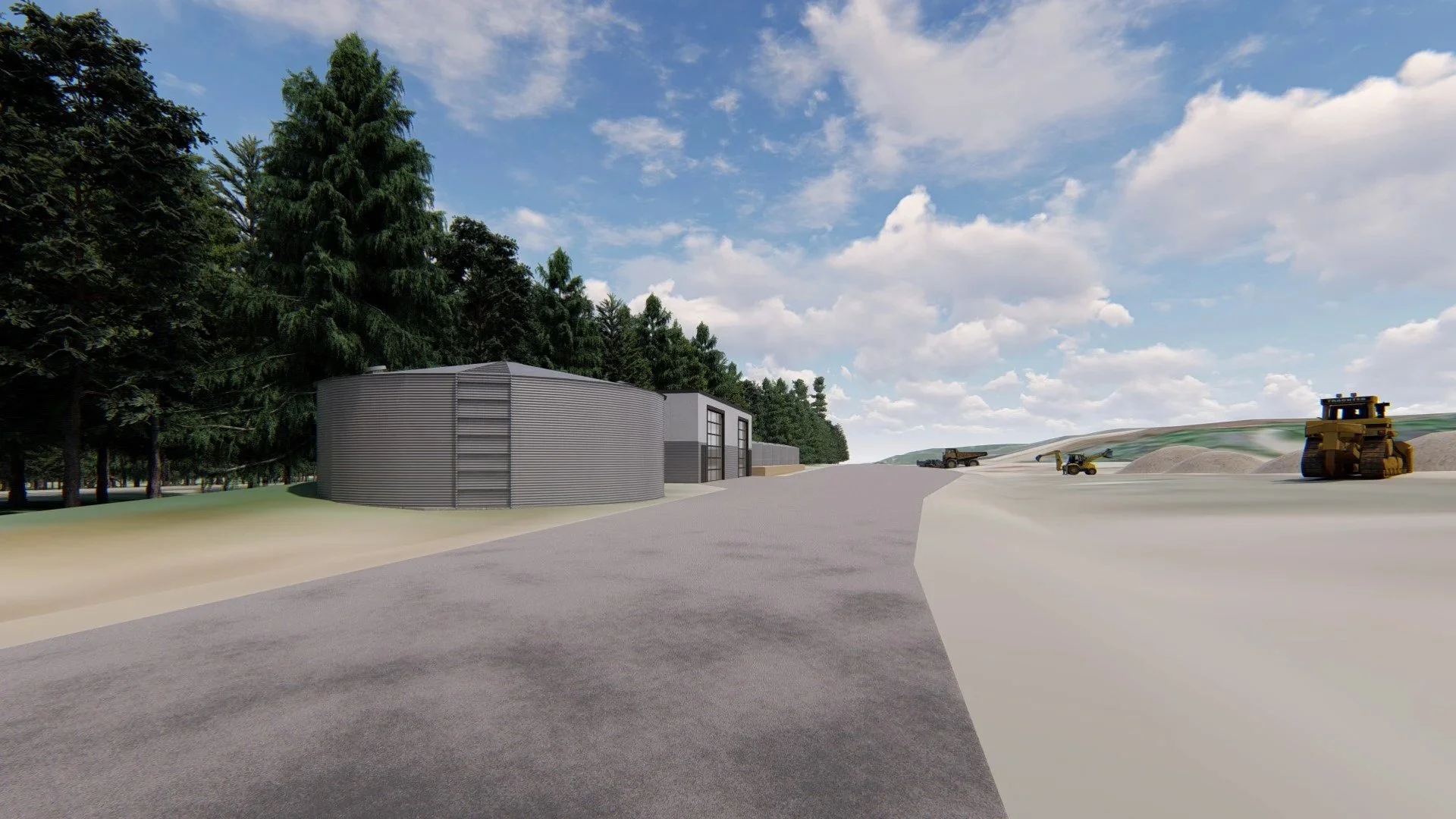

On-location treatment partnerships for landfills.

Safe and effective treatment of leachate is a growing problem for landfill operators as volumes increase annually, alongside increasingly stringent regulations. Fluctuating climate conditions affect the reliability of solutions such as membrane bioreactors (MBR), leaving operators faced with alternatives that are unsustainable or cost prohibitive.

Invested in the outcome.

We collaborate with landfill operators under long-term partnerships. This model enables us to support landfills over the lifetime of the facility, easily handling the variable elements of leachate that occur over time.

Depending on the situation at a given site, our team can design a solution to maximize the efficiency of your current system by adding or augmenting treatment components, or we can configure a plant on site and redirect feedstock into our system.

Our standard plant design.

Can process 100,000 gallons per day, can be scaled to suit

Configured with 200,000 gallon buffer tanks to store overflow in the case of large water or storm event

Typical combinations include modular and scalable non-biological equipment processes, built to suit or implemented to augment your current solution to maximize operational efficiency

In-line and on-site monitoring of feedstock water for better chemistry management to get the most out of every stage

Zero-liquid discharge system uses filtration and advanced oxidation to remove the constituents, including ammonia, cost-effectively

Effluent can be discharged to the local publicly owned treatment works (POTW) or to the environment depending on site specific conditions and treatment targets

Low-touch, effective water treatment for construction and development sites.

High turbidity water accumulation from seasonal rainfall or existing groundwater can slow your project down. If the water is contaminated with heavy metals or hydrocarbons, safe removal and discharge becomes even more complicated. Our treatment systems are self-dosing, portable and modular. System components can be added or removed to meet the fluctuating water conditions on your site.

Remove solids from your water for safe discharge to storm, sewer or re-use on site.

GRT’s reagent dosing process:

Tailors reagent selection to the specific application

Solids settle in the tank, and clean water flows out of the bin

Hands-off, worry-free operations

Cost effective, reliable solution for construction and remote camps

Pump the water to our bin, it can gravity flow down to the sewer or use the integrated discharge pump to discharge the water further or to higher elevations

Additional treatment steps can be added as needed to remove metals or hydrocarbons prior to discharge